Factory

Clean oil mist-rich working environment to the

regulated level of office air quality!

-

Stabilizes product quality and improve work environment safety

-

Proactively responds to the Serious Industrial Accident Act by preventing industrial accidents

such as lung cancer among workers

Processes where oil mist is generated,

such as CNC machining and rolling are causing problems with occupational diseases among workers, including lung cancer.

Khanfilter’s oil mist-rich working environment improvement solution

contributes to preventing industrial accidents, including various cancer and safety accidents (such as floor slippage), as well as reducing management risks by proactively responding to the Serious Industrial Accident Act.

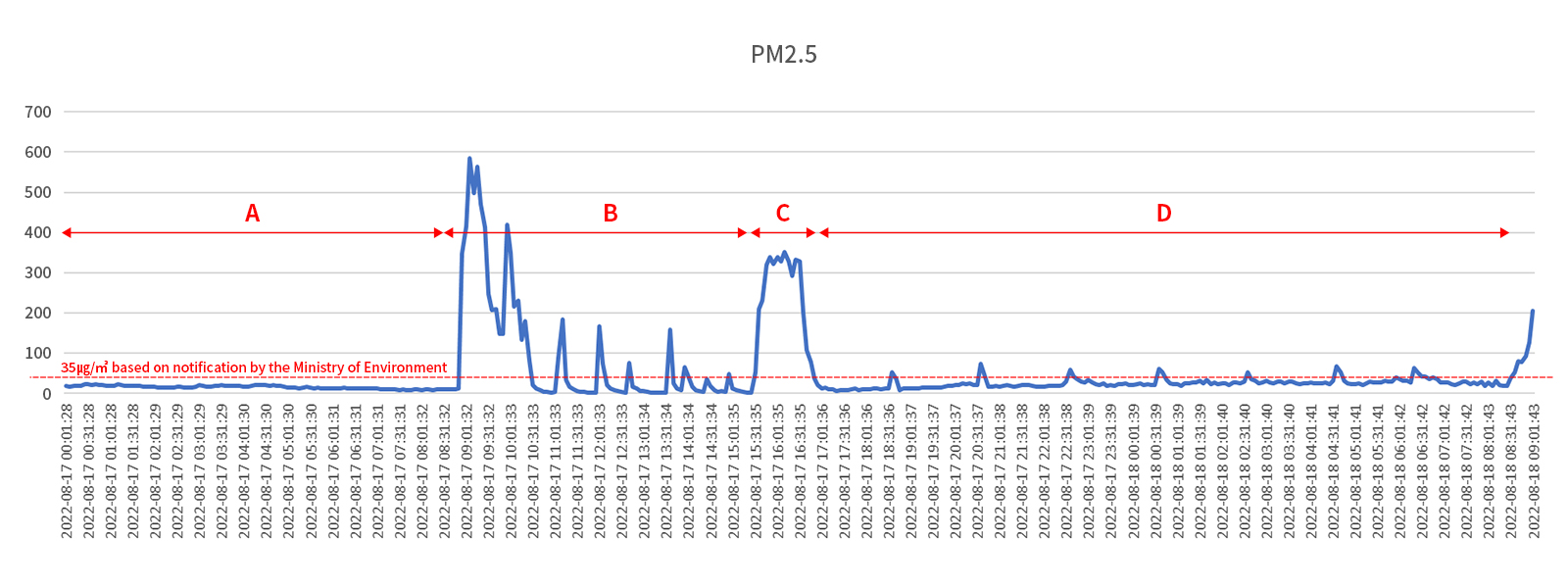

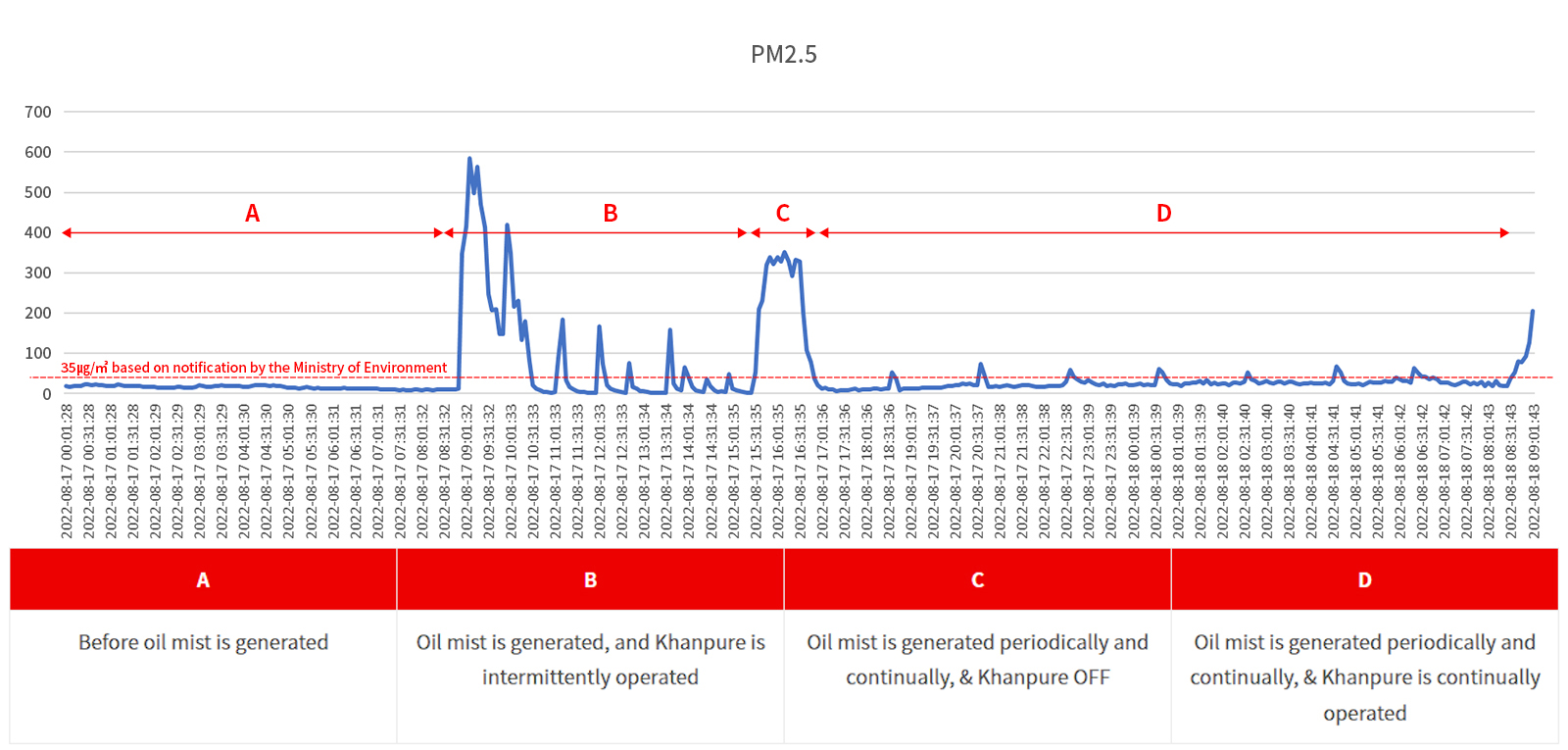

| A | B | C | D |

|---|---|---|---|

| Before oil mist is generated | Oil mist is generated, and Khanpure is intermittently operated | Oil mist is generated periodically and continually, & Khanpure OFF | Oil mist is generated periodically and continually, & Khanpure is continually operated |

In case of KhanPure turned off : Oil mist condition is 20 times higher than the regulated level for the office

In case of KhanPure operated : Air quality has improved to office level

Reducing air pollutants and odors without using LNG

Khanpure, a solution for reducing greenhouse gas/energy consumption

-

Technology in place of air pollution prevention facilities RTO*!

-

Maximizes energy efficiency by not using LNG and reducing electricity consumption to 25%

-

Costs are saved, and annual greenhouse gas (CO2) generation is reduced by more than 85%

Reducing air pollutants and odors without using LNG

Khanpure, a solution for reducing greenhouse gas/energy consumption

-

Technology in place of air pollution prevention facilities RTO*!

-

Maximizes energy efficiency by not using LNG and reducing electricity consumption to 25%

-

Costs are saved, and annual greenhouse gas (CO2) generation is reduced by more than 85%

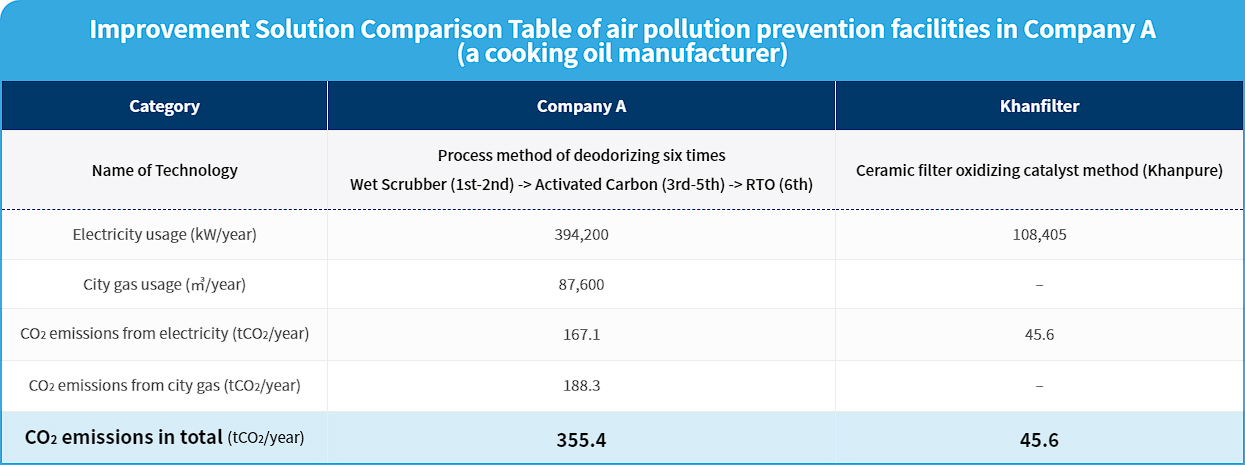

Unlike air pollution prevention facilities

such as RTO that use LNG, Khanfilter is a technology using ceramic filters and oxidation catalysts that decomposes collected PM and odor particles by catalyst reaction and discharges them.

While practicing carbon neutrality and establishing smart ecological factories, it contributes to resolving community complaints such as air pollution and odor problems.

Improvement Solution Comparison Table of air pollution prevention facilities in Company A

(a cooking oil manufacturer)

(a cooking oil manufacturer)

| Category | Company A | Khanfilter |

|---|---|---|

| Name of Technology | Process method of deodorizing six times Wet Scrubber (1st-2nd) -> Activated Carbon (3rd-5th) -> RTO (6th) |

Ceramic filter oxidizing catalyst method (Khanpure) |

| Electricity usage (kW/year) | 394,200 | 108,405 |

| City gas usage (㎥/year) | 87,600 | – |

| CO2 emissions from electricity (tCO2/year) | 167.1 | 45.6 |

| CO2 emissions from city gas (tCO2/year) | 188.3 | – |

| CO2 emissions in total (tCO2/year) | 355.4 | 45.6 |

* RTO (Regenerative Thermal Oxidizer)