Even in oil mist and water vapor situations

Continuous performance is maintained / DPF technology is applied

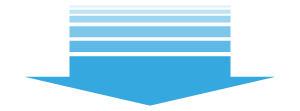

Dust collection rate changes over time when used without cleansing

Carbon Neutral TECH.

Ceramic filter (semi-permanently usable)

No waste and no wastewater are generated, maintenance and energy costs are saved

(collection of oil mist/PM)

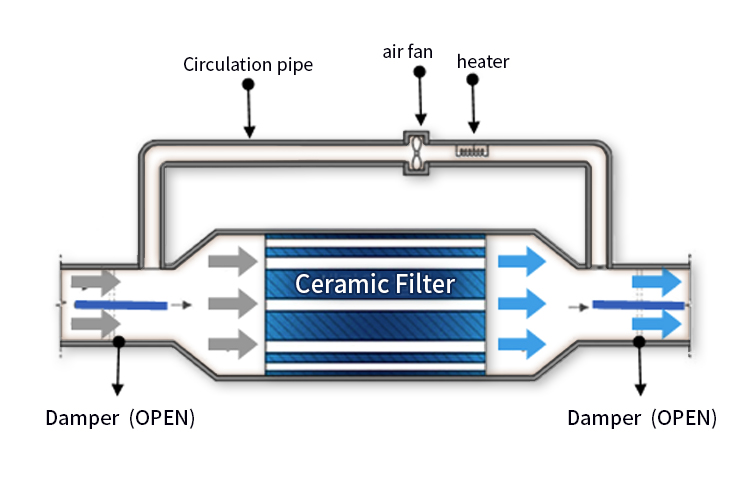

[Filtering process - No electricity used]

Ceramic filter used : Performance is maintained even in oil mist and

water vapor environments.

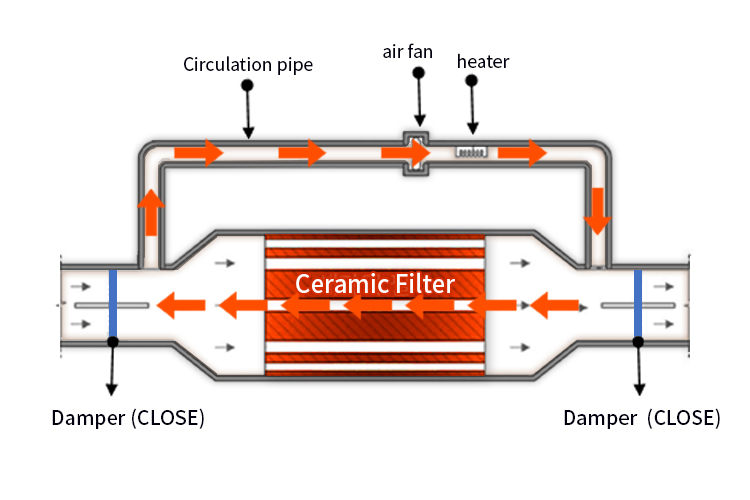

(filter regeneration)

[Self-cleaning process-catalytic reaction]

Self-Cleaning : oxidation and decomposition of oil mist and PM collected

by catalytic reaction after business is over.

Comparison of competitive technologies in oil mist- and water vapor-rich environments

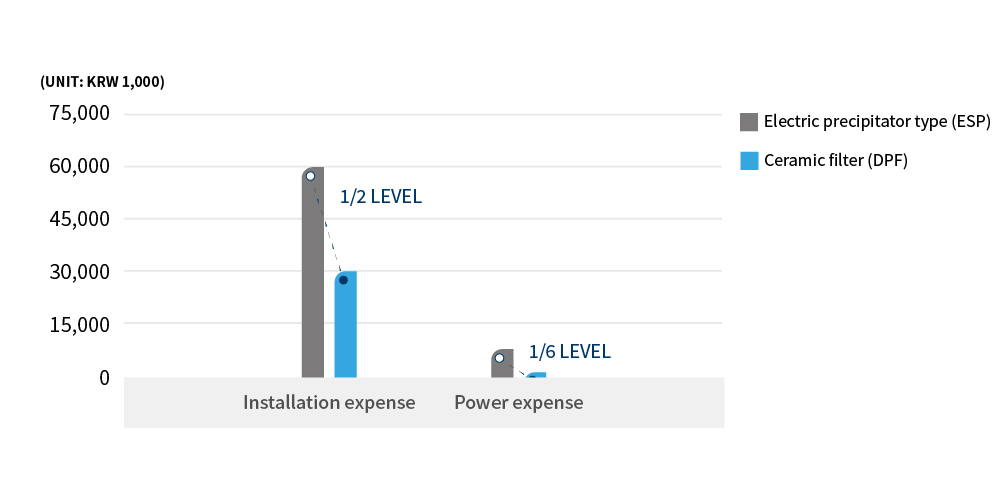

Energy usage: 120kWh

*1.2kW (300W cell × 4), 10 hr of operation a day, for 10 days

Much of the wastewater generated causes a high environmental load.

*In the United States, separate wastewater treatment equipment is required.

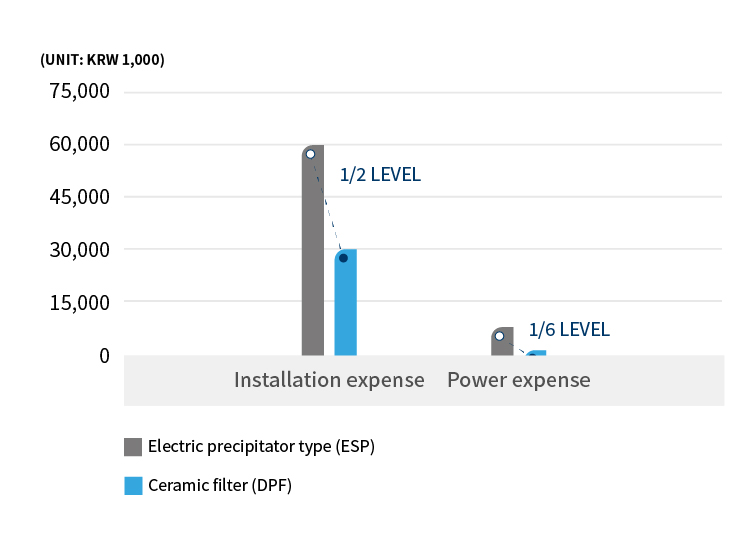

Energy usage : 22kWh, 1/6 level

*In the case of one self-cleaning every 10 days

technology produces no wastewater.

Filter replacement is made at least once every 2 to 3 days

to maintain kitchen ventilation performance.

➔ Generates large amounts of waste

*There is no competitive technology optimized for kitchen ventilation.

No filter replacement, No waste generated

The only, technology that can be continuously used

in oil mist- and water vapor-rich kitchen spaces

*Simple maintenance is required once a year

All-in-One TECH.

Not only removes PM but also sterilizes germs, viruses and removes odors at the same time.

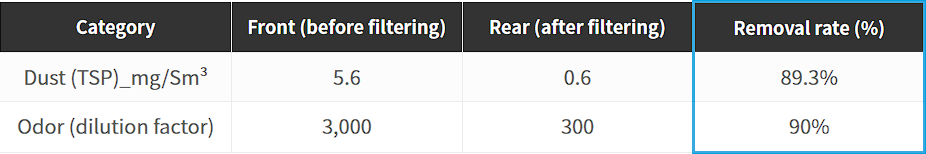

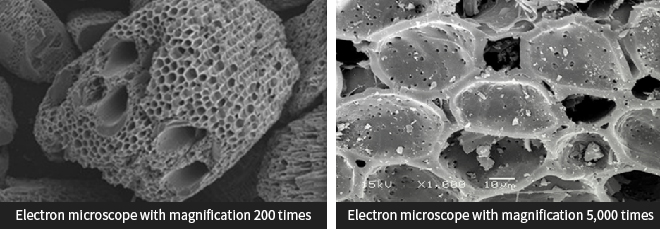

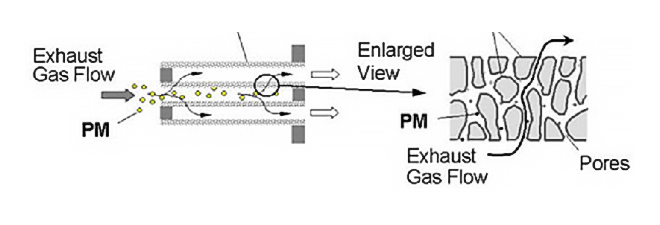

The ceramic filter of DPF with a porosity of 50% or higher adsorbs PM and odors at the same time.

Unlike activated carbon, which requires replacement, the filter is refreshed by the decomposing process of the catalytic reaction during the self-cleaning process.

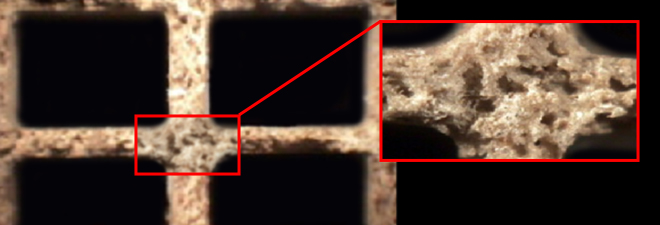

[Microstructure of activated charcoal]

Powerful dehumidification and deodorization power

from mysterious pores!

Can you see the mysterious pores of activated bamboo charcoal?

The surface area of 1g of Hole & Hole Activated Bamboo Charcoal is about 1,200m². This is a result of the activated bamboo charcoal’s spread numerous pores, whose large surface area is what drives the adsorption of different scents and moisture. This is the reason why Hole & Hole Activated Bamboo Charcoal powerfully adsorbs a variety of odors and moisture in daily life.

Structure and Principles of the DPF Ceramic Filter

Microstructure of Ceramic Filters (DPF)

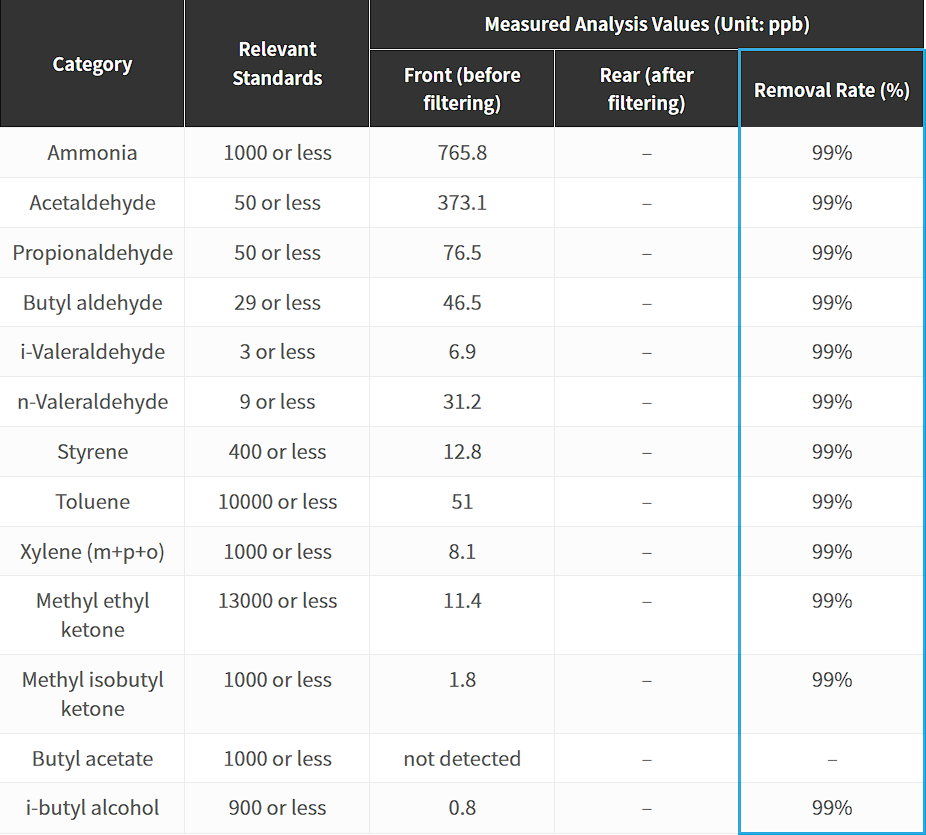

Performance of reducing harmful gaseous substances

(Osan-si Udo Galbi, 2018.12)

| Category | Relevant Standards | Measured Analysis Values (Unit: ppb) | ||

|---|---|---|---|---|

| Front (before filtering) | Rear (after filtering) | Removal Rate (%) | ||

| Ammonia | 1000 or less | 765.8 | – | 99% |

| Acetaldehyde | 50 or less | 373.1 | – | 99% |

| Propionaldehyde | 50 or less | 76.5 | – | 99% |

| Butyl aldehyde | 29 or less | 46.5 | – | 99% |

| i-Valeraldehyde | 3 or less | 6.9 | – | 99% |

| n-Valeraldehyde | 9 or less | 31.2 | – | 99% |

| Styrene | 400 or less | 12.8 | – | 99% |

| Toluene | 10000 or less | 51 | – | 99% |

| Xylene (m+p+o) | 1000 or less | 8.1 | – | 99% |

| Methyl ethyl ketone | 13000 or less | 11.4 | – | 99% |

| Methyl isobutyl ketone | 1000 or less | 1.8 | – | 99% |

| Butyl acetate | 1000 or less | not detected | – | – |

| i-butyl alcohol | 900 or less | 0.8 | – | 99% |

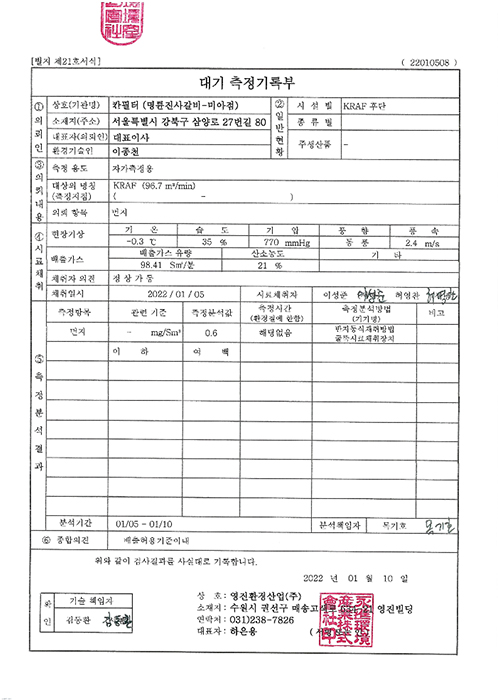

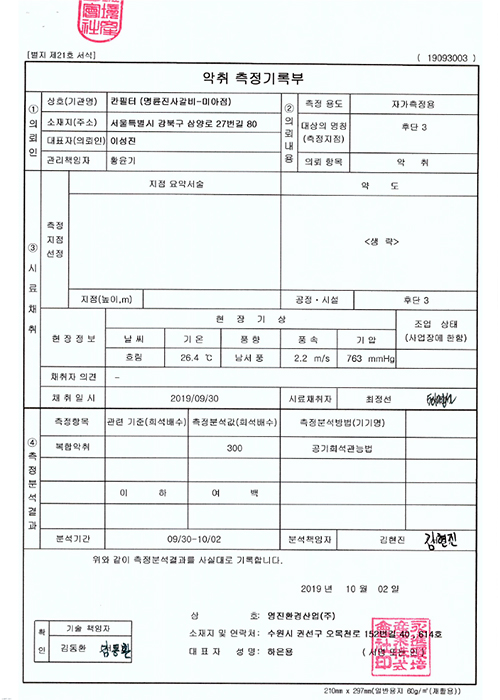

Odor Measurement Register

Air Measurement Register